What happens next with used tires?

Used tires have so far been a burden for manufacturers rather than an opportunity. Their collection and recycling have been cumbersome, and even though technology has long enabled it, tires have not been effectively redirected into a new cycle in Estonia. Instead, they have been stored in urban areas, buried, or their management has simply been avoided. With the support of our partners, ETR introduces an innovative chemical recycling process to the market, which enables the valuable materials found in used tires to be redirected into a new cycle.

How do we do it?

A fully transparent solution

ETR, partners, and our roles

Tire collection

ETR is a new producer responsibility organization whose role is to develop and manage a tire collection network to redirect used tires back into circulation in accordance with principles of sustainability.

Pre-processing

Ragn-Sells is a Swedish family-owned company with a 141-year history, focused on circular and recycling solutions. Ragn-Sells is involved in preparing tires for pyrolysis, removing metals from tires, and granulating rubber.

Final processing

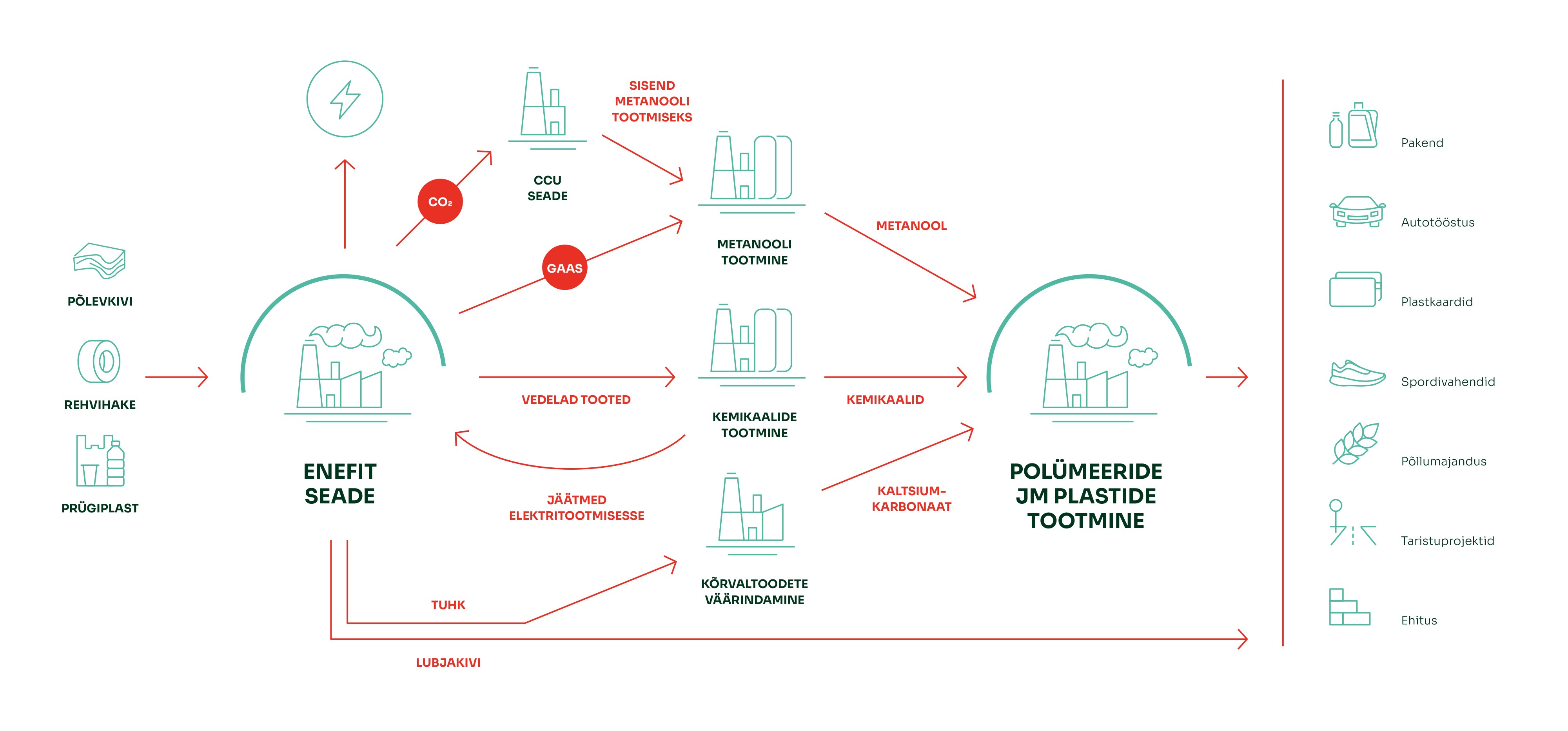

Enefit is an Estonian state-owned energy and chemical group, responsible for the final treatment of tires in Auvere and their conversion into raw materials that can be used in various industrial sectors.

Innovative processing solution

Process